Magnetic shielding actuator

Magnetic shielding is an important aspect for precision mechanical actuators for MECAL to stabilize frames for machines in the chip industry. Magnetic fields can interfere with the sensitive electronics used in industry. Multiphysics Finite Element Method simulations are used to simulate the actuators and determine which parts have the most influence on the magnetic shielding. The simulations concern both static and dynamic magnetic fields. The interest in MECAL lay mainly in the low frequency region of magnetic shielding, typically between stationary behavior and a few kHz.

Design of magnetic shielding

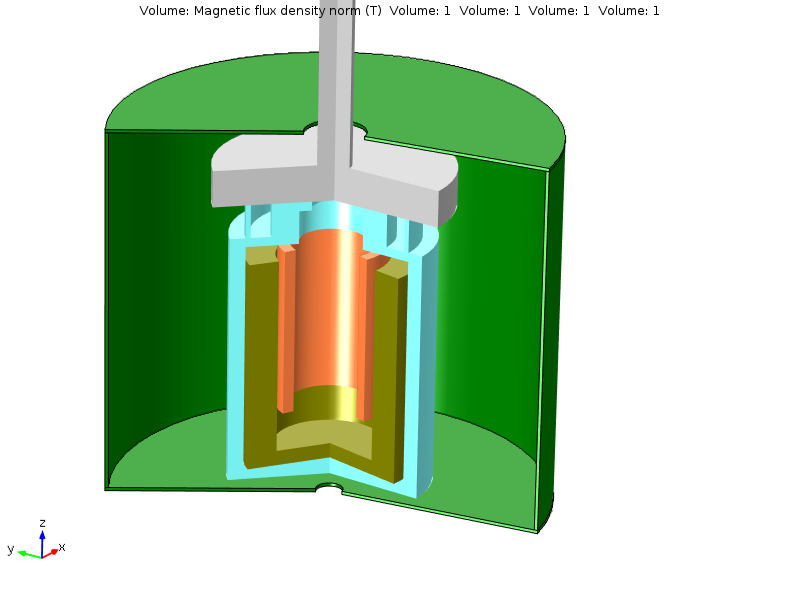

The current design was entered into the Finite Element Method (FEM) model, and the stationary fields were determined. Very important are the non-linear input data of the materials from the supplier. An optimal design of the shielding was determined by Physixfactor, which allowed immediate savings on material costs for this part.

Magnetic shielding for actuators protects sensitive electronics from stray magnetic fields or contains the actuator’s field to prevent interference, typically using high-permeability materials (like soft iron) to redirect field lines, often in thin, custom shapes with holes for specific designs, crucial in precision systems like chip manufacturing or robotics. This shielding reduces magnetic cross-coupling between closely spaced actuators, improving system stability, though modeling it accurately can be complex

Preventing magnetic cross-coupling

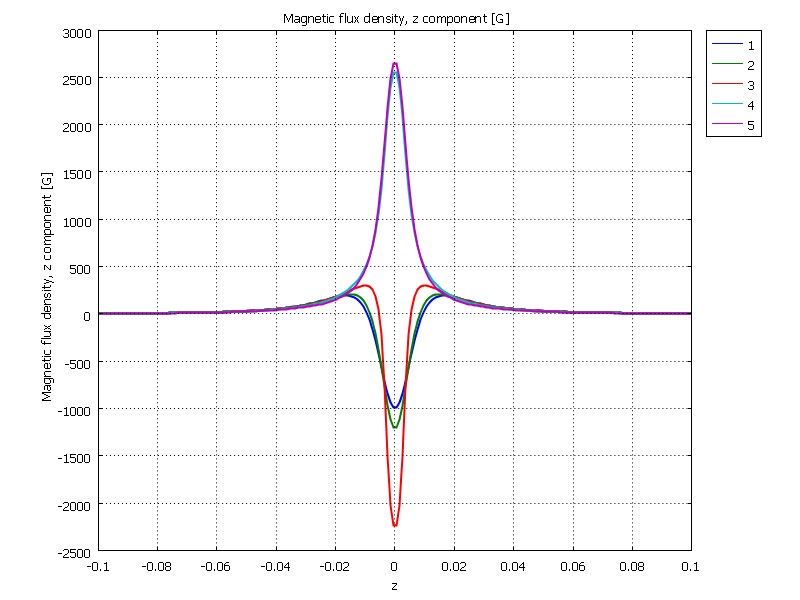

In the actuator it is important to gain a good insight into the course of the Magnetic Flux Density. Within the finite element software, material definitions can be chosen in which the properties are not linear. In the left figure we see a graphical impression of the progression along the axis of symmetry and preventing magnetic cross-coupling.